Long range OGI Optical gas detection thermal infrared flir imaging custom systems from SPI

Contact SPI for a total PTZ multi sensor custom OGI Gas detecting IR imaging solution gimbal built to your exact requirements.

Oil and Gas producers have to take on a range of responsibilities, from detecting leaks to meeting environmental regulations, maintaining site security and system integrity. How companies address these issues often depends upon whether they are upstream, midstream, or downstream producers.Government regulation, concern for the environment, personnel safety and economic considerations have made locating hydrocarbon and other gas leaks a priority for today’s energy industries.

Most industrial gases and chemical compounds emitted are invisible to the naked eye. Companies use a wide variety of tools to monitor, identify and contain these compounds both upstream in exploration and production, downstream in refining and distributing, and during transport. Infrared imaging allows workers to detect volatile organic compounds (VOC) that cannot be seen by the human eye. Infrared cameras are able to visualize the presence of fugitive emissions that are often odorless and invisible and are also toxic or flammable. More specifically, mid-wave infrared (MWIR) cameras are spectrally optimized to image at the peak absorption wavelength of many VOC’s. Currently handheld devices are being used to identify these fugitive emissions.

The Environmental Protection Agency (EPA) has suggested that by using optical gas imaging (OGI) technology, an organization can increase the number of pieces of equipment that can be inspected and therefore reduce the cost of identifying the leaks. It is of vital importance that the organization is able to obtain as complete a picture as possible of the condition of the plant to enhance safety, efficiency and profitability, as well as to be environmentally responsible. OGI cameras offer a full picture of all equipment at once, and the leaks appear as “smoke” when viewed on your computer’s monitor. Surveilling a large area at once allows you to rapidly detect sources of emission, and quickly respond to repair or replace faulty equipment.

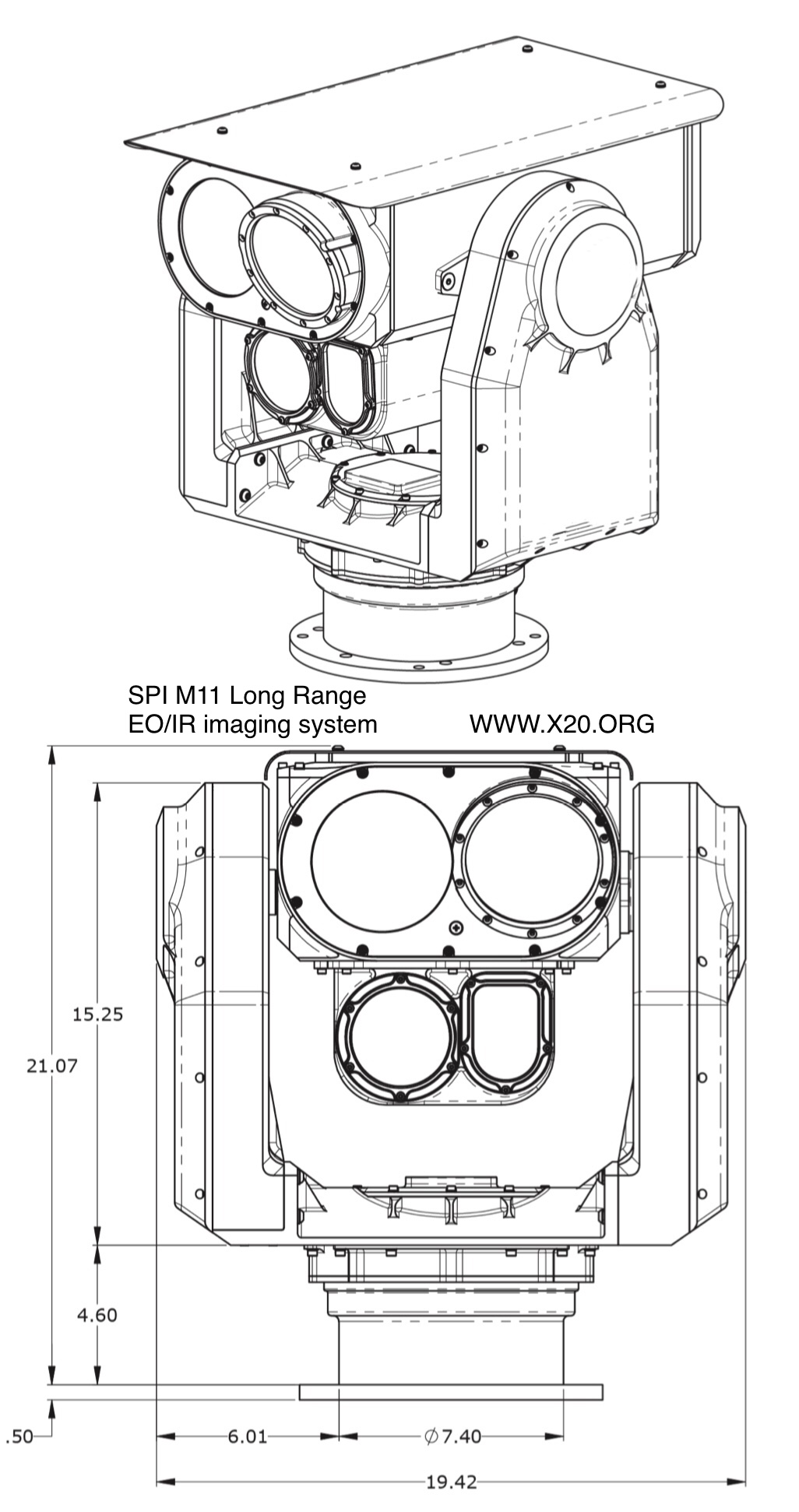

SPI Offers a wide array of remote sensing standalone, Pan Tilt Zoom (PTZ), airborne, and ground based gas detection and quantification payload camera systems catered for various short, medium and long range applications

By identifying leaks faster, organizations can minimize emissions, reduce unaccounted gas and reduce the amount of man hours it takes to conduct ongoing inspections. Leaks from process equipment, no matter how small, not only pose a danger to the environment, but they also represent an economic loss to the company. OGI camera cores can be used to detect gas from many different sources. Some of the most common sources are: • Flanges • Valves • Plugs and Caps • Couplings • Pump seals • Drain covers • Instrument Connections To sum it up, the use of OGI cores provides the ability for better planning and scheduling., Additionally, to the early identification of compliance issues reduces fines and allows your organization to become a better steward of the environment. OGI cores are a fit for all areas of the oil and gas industry: • Petrochemical and Oil Refining • Pipelines • Chemical • Power Generation • Natural Gas • Leak Detection and Repair (LDAR) • Regulators When it comes to leak detection in the oil and gas industry, the use of cameras based on mid-wave infrared (MWIR) technology is a must.

When we look for leaks, the majority of hydrocarbon gas compounds we inspect for in the oil and gas industry have a peak absorption in the 3.2 – 3.5 micron wavelength region of the electromagnetic spectrum. This the most sensitive and efficient area for a number of infrared detectors, including those used in the NiatrosTM optical gas imager. Although there are a number of gases that absorb in the 7-14 micron wavelength region, for environmental purposes, the primary concern is with methane and similar VOC’s which can only be “seen” with a properly configured MWIR camera.

OGI cameras are specially configured to detect infrared radiation from approximately 3.2μm to 3.5μm. This, combined with the high sensitivity of the cooled MWIR photon detectors incorporated in these cameras, makes this technology ideal for detecting hydrocarbon gases that emit within that region, including: • Butane • Benzene • Ethane • Ethylbenzene • Ethylene • Heptane • Hexane • Isoprene • MEK • Methane • Methanol • MIBK • Octane • Pentane • 1-Pentane • Propane • Propylene • Toluene • Xylene Even small leaks, if left unattended, can cause extensive damage to your equipment, the environment and your bottom line. systems are available for Airborne OGI gas hyperspectral imaging.

Methane is a powerful greenhouse gas and many regulatory bodies around the world are taking significant steps toward sharply reducing its emissions from the oil and gas sector at long ranges. A large portion of such emissions comes from a small fraction of “super-emitting” sources. Long range PTZ Airborne thermal flir infrared hyperspectral imaging can visualize and quantify these emissions and gas leaks under various environmental conditions at short, medium and long ranges.

The capabilities of aerial manned or unmanned methane emission detection systems were recently demonstrated in a measurement campaign composed of multiple controlled releases with methane flow rates varying from 3 to 55 cubic meters per hour (m3/h). The results of this demonstration show that these systems can detect methane emission rates as low as 3 m3/h as well as a parity slope of 0.99, which indicates strong agreement between commanded leak rate and retrieved leak rate. Based on the data collected during these tests, airborne thermal IR OGi (Optical Gas Imaging) infrared hyper-spectral visualization is a highly efficient and sensitive tool for the detection and quantification of methane leaks.

Because an OGI camera core is constantly observing the facility and can detect leaks remotely from a distance, you can identify and eliminate the small leaks that can result in a significant loss of product over time and impact your bottom line. Additionally, a long range OGI MWIR camera core can be used at any point in the facility and equipment life cycle – including during production or equipment start- up.

SPI Offers a wide array of remote sensing standalone, Pan Tilt Zoom (PTZ), airborne, and ground based gas detection and quantification payload camera systems catered for various short, medium and long range applications.